Yes, we can put your LOGO on mould surface via engraving .

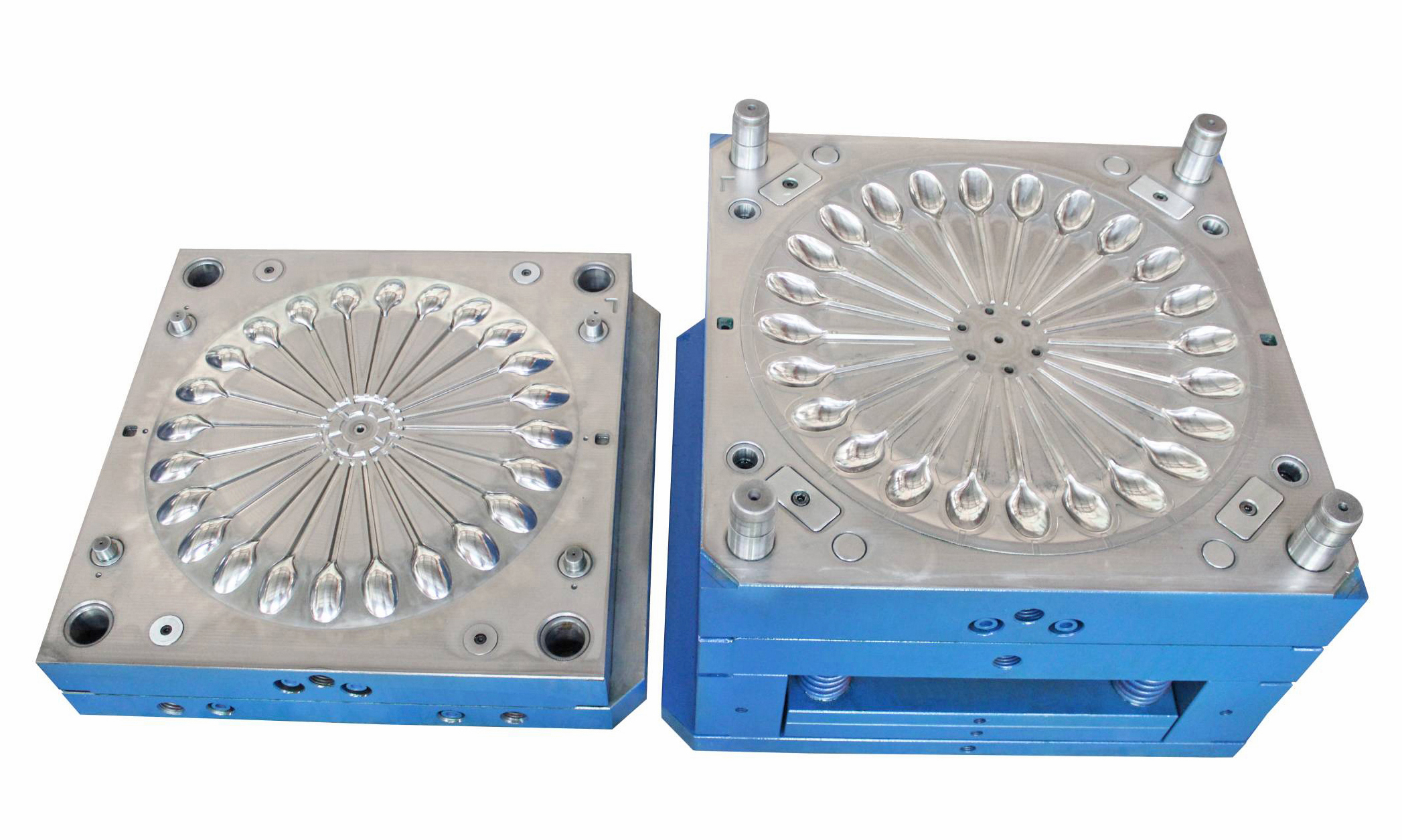

We supply Southeast Asia,Pakistan,Latin America clients for nearly 200 sets per year,together with other countries at least 400 sets in total.

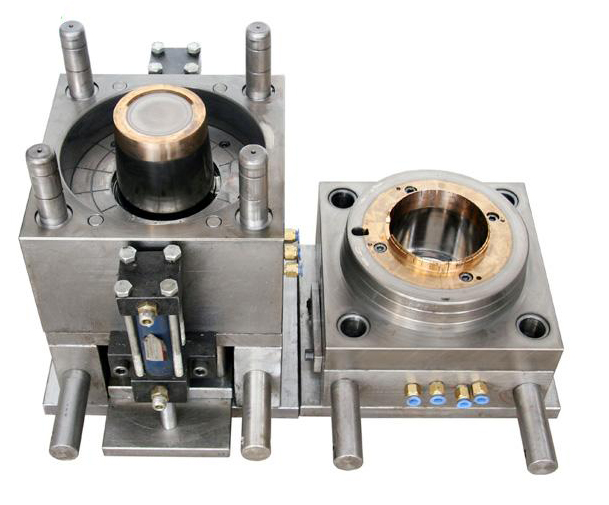

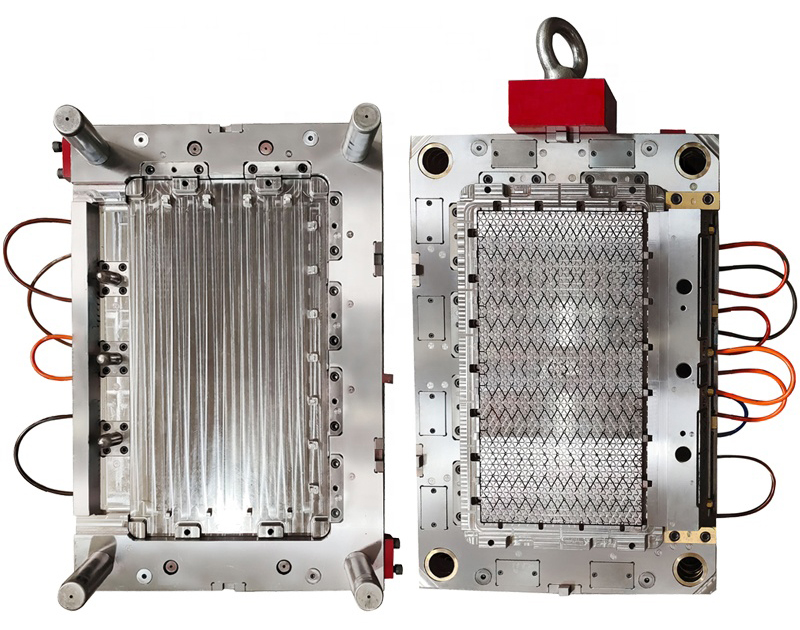

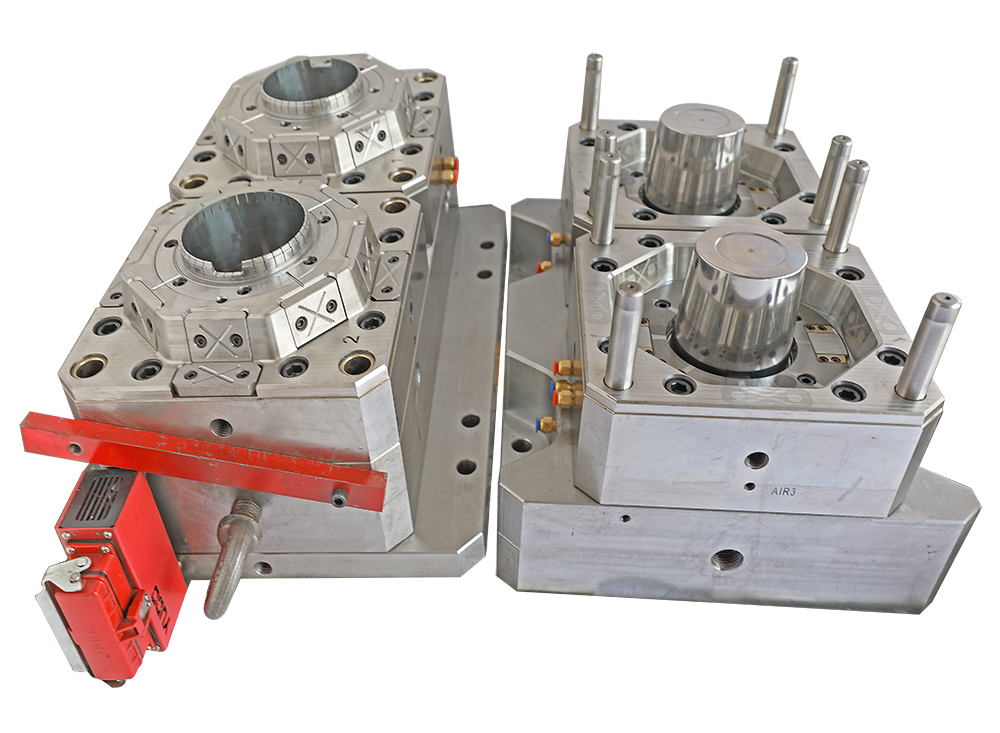

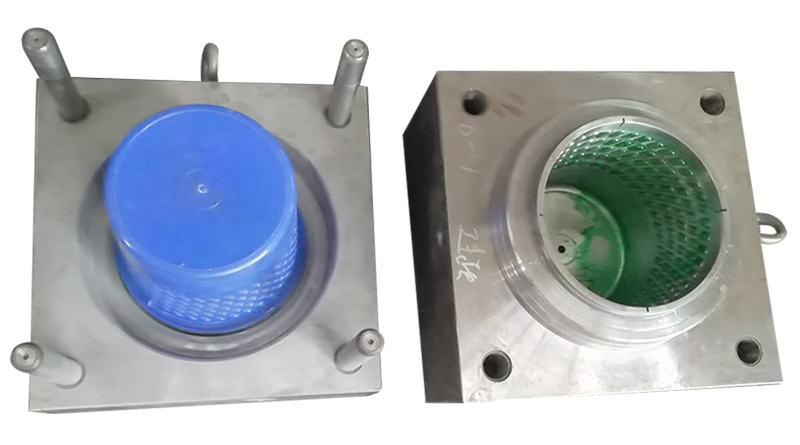

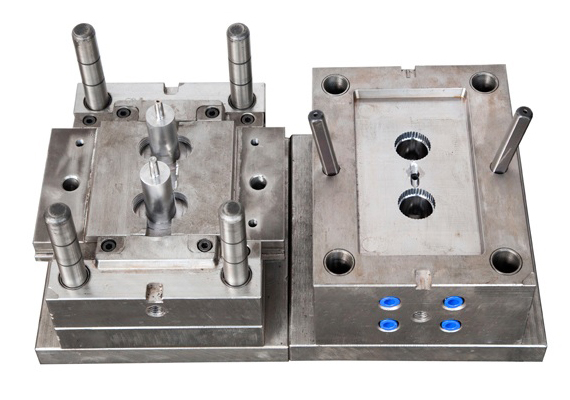

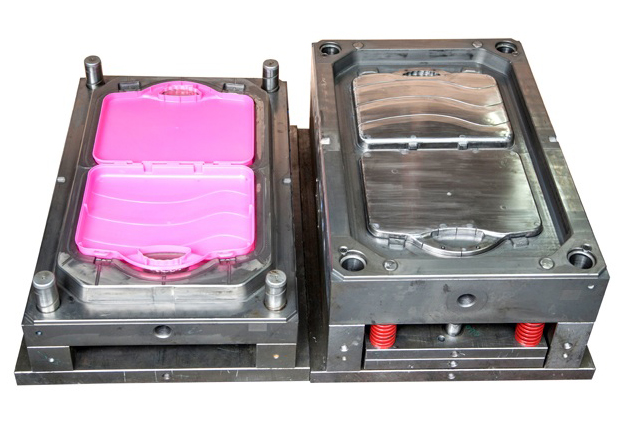

Normal mould tolerance of 0.005mm while product tolerance of 0.02

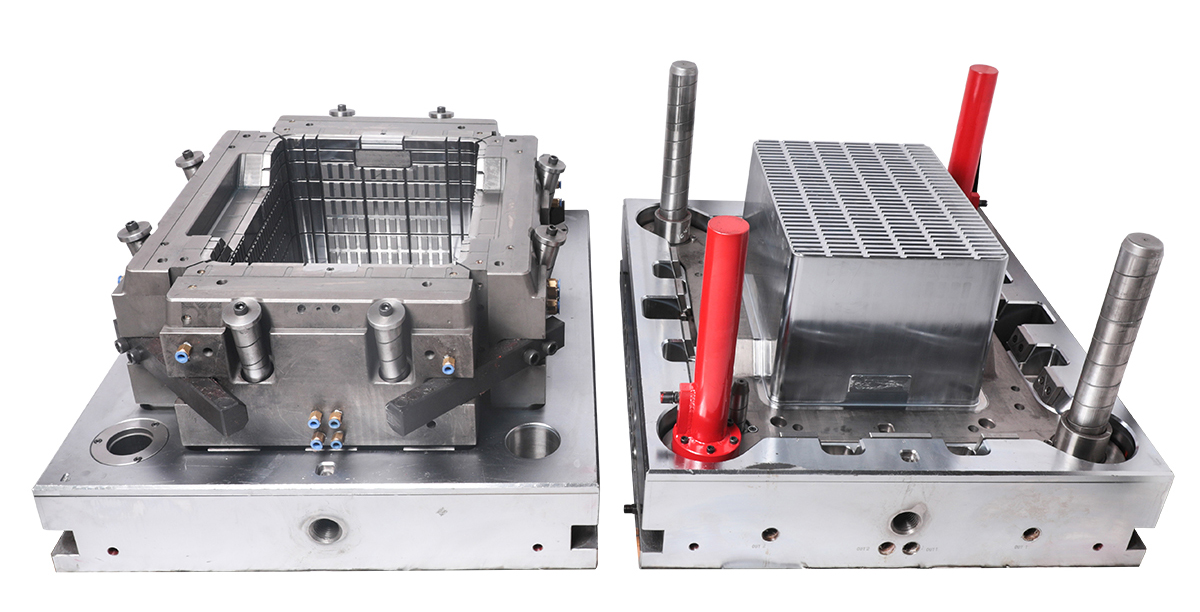

Role of heat treatment in mold manufacturing:

– Increase hardness and wear resistance, thus improving its life.

– The strength is strengthened and the deformation is reduced to ensure the accuracy and precision stability of the mould.

By T/T, L/C, Trade Assurance, Western Union.

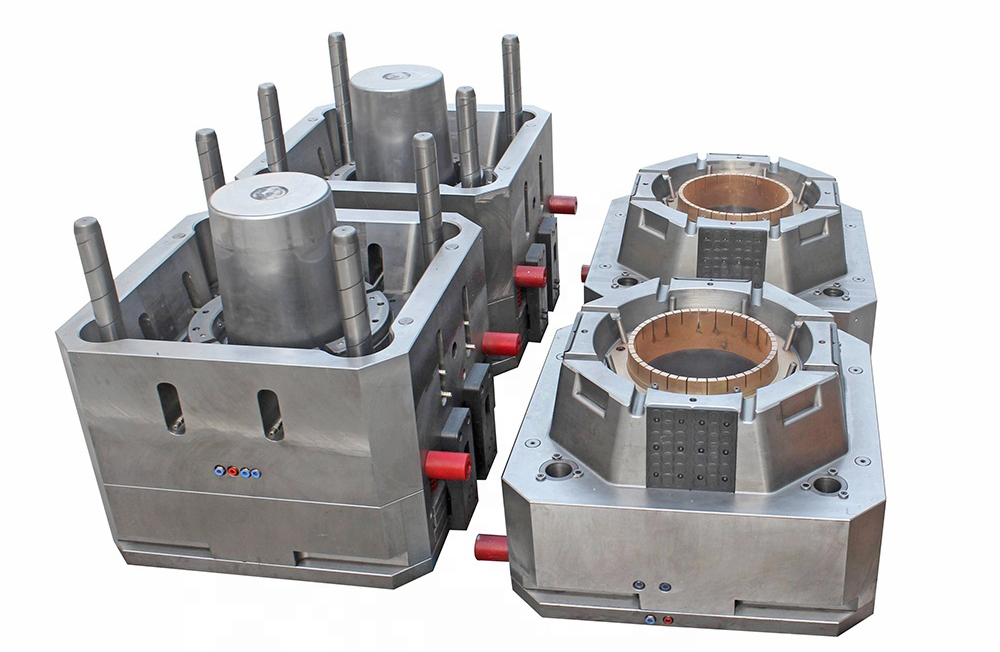

We usually use steel of P20, 718H, H13, S136, NAK80 and etc.

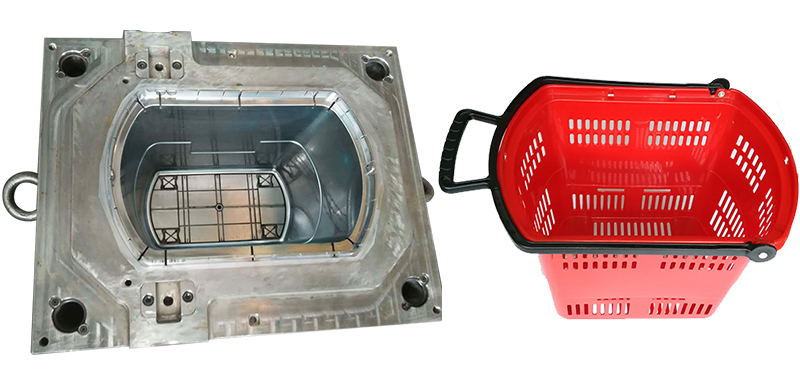

It depends on how many parts are needed and the complexity of the part geometry. Simple moulds can be completed in two weeks or less. The typical lead time is between 4-6 weeks, but some complex parts could take two months to design and manufacture the tool.

We have a complete management system. From order confirmation to shipment, our project dept. will take charge of the order wholly. We will report the order status periodically.

The following is our mould production flow chart:

-Product design

-Customer confirm the product design, then start the mould design

-After the mould design confirmation, then place the production list

-Mould base and components purchasing and production

-Follow the tooling process by processing dept.

-1st Mould testing (or 2nd Mould testing if necessary), check the product dimension and take down the mould testing report.

-Send the testing sample to customer for improvements or confirmation, and instruction of mould shipping.

-Mould packing and shipment, together with mould operation instruction, mould assembling drawing, spare parts list and mould quality certificate.

The mould life depends on the steel you choose.

For example, If P20 steel, the mould life can be 500,000 shots;

If H13 / S136 steel, the mould life can be 1 million shots.

Generally, all our mould will be packed first with stretch film and put inside wooden box and fastened by iron strap.